Attic Fan Belt Deflection

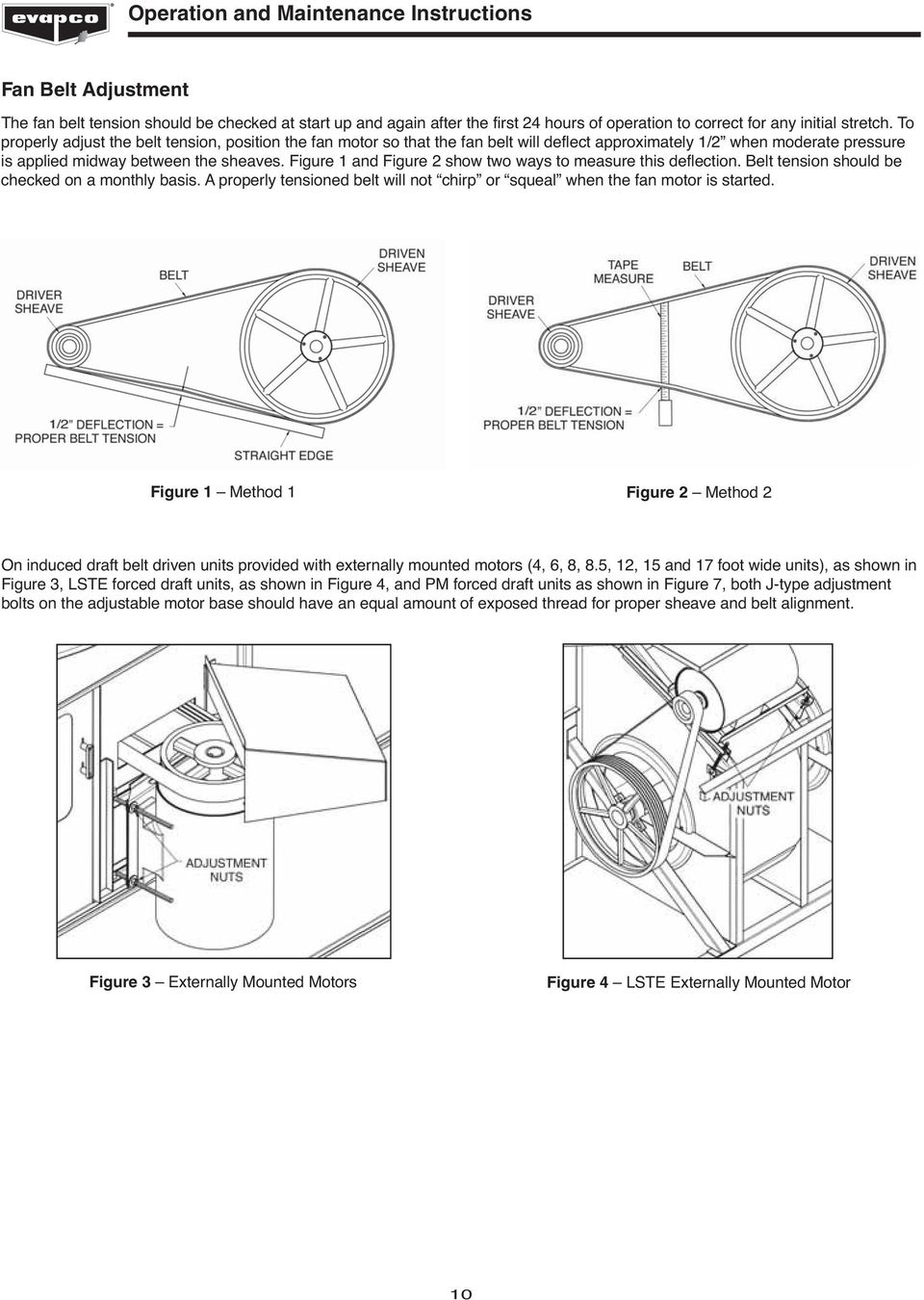

The correct tension method is to get the belt close to the correct tension by feel with a deflection of 1 64 of an inch for every 1 of distance between the two pulley centers.

Attic fan belt deflection. So for a 32 span the deflection amount would be 32 64 or 1 2. The force f to apply is shown per belt in the table to the left. Desired belt deflection is 1 64 of an inch for every inch of belt span. The force shown in the table is per rib.

A space between the belts should be about 1 3 4 at proper belt tension. Set the small o ring on the tensiometer to the zero mark. Pull one end of the old fan belt off from around the hub connected to the motor shaft. Conversely an improperly tensioned belt can cause a host of easily preventable problems including noise vibration poor fan performance bearing wear and shortened fan motor life.

Test belt tension with power off squeeze belt together with light force. Dispose of the broken fan belt or pieces of the belt in the trash. To deflect the belt 1 64 for each 1 of belt span q. Adjust the motor back until there is approximately 1 2 1 3 cm to 3 4 1 9 cm deflection at the center of the belt with light pressure.

You can then use an app or a chart like this one to find the proper force to generate this deflection. Slowly rotate blade one full revolution by hand to. Pull the other end of the belt off the other hub inside the fan. So for a 5 rib belt you will need to multiply the force shown in the.

Lift the belt out of the fan if the fan belt is broken in half pull the two sections off the hubs and lift them out of the fan.